Call us at 732 292-1994 or 800 867-6690 | Email us at triadscientific@gmail.com | Visite us on

PLANET BEST

Lab Instrumentation

Lab Equipment

Lab Furniture

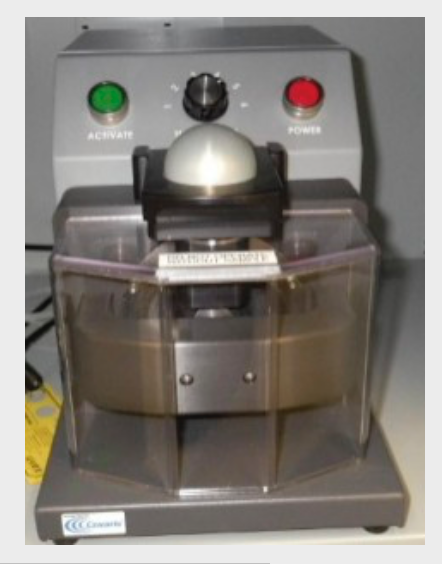

Retsch XRD-Mill McCrone Retsch Mill NEW

Mills >> Retsch XRD-Mill McCrone Retsch Mill NEW

Retsch XRD-Mill McCrone Retsch Mill NEW

"The XRD-Mill McCrone was specially developed for the preparation of samples for subsequent X-ray diffraction (XRD). The mill is used for applications in geology, chemistry, mineralogy and materials science, quality control as well as R&D.

Because of its unique grinding motion, the XRD-Mill McCrone is particularly effective for this analytical method: The 48 cylindrical grinding elements grind the samples gently via friction. The result is a short grinding time with almost no sample loss and an exceptionally narrow particle size distribution.

The crystal lattice is almost entirely preserved during grinding operation, a premise for meaningful X-ray diffraction.

The grinding vessel consists of a 125 ml capacity polypropylene jar fitted with a screw capped gasketless polyethylene closure. The jar is filled with an ordered array of 48 identical cylindrical grinding elements, available in agate, zirconium oxide or corundum. The grinding time for optimum micronization is between 3 and 30 minutes. A typical sample volume is between 2 and 4 ml." (RETSCH)

Application Examples:

bones, borides, carbides, cement, ceramics, clay, construction materials, glass, metals, mica, minerals, nitrides, plant materials, slate

Product Advantages:

crystal lattice preserved during grinding operation

very narrow and reproducible particle size distribution

minimal cross contamination

compact, bench-top sized model

adjustable grinding power (4 steps)

suitable for dry and wet grinding

easy to clean

almost maintenance-free

quiet operation

Features

| Applications | grinding, mixing and triturating, dry and wet |

| Field of application | X-ray diffraction |

| Feed material | medium-hard, hard, brittle, fibrous |

| Material feed size* | < 0.5 mm |

| Final fineness* | < 1 µm |

| Speed at 50 Hz (60 Hz) | 1,000 - 1,500 min-1 in 4 steps |

| No. of grinding stations | 1 |

| Typical mean grinding time | 3 - 30 min |

| Dry grinding | yes |

| Wet grinding | yes |

| Cryogenic grinding | - |

| Material of grinding tools | agate, zirconium oxide, corundum |

| Grinding jar sizes | 125 ml |

| Setting of grinding time | digital, 00:00:10 to 99:59:50 |

| Drive | DC-Motor |

| Drive power | 50W |

| Electrical supply data | 220-240 V, 50/60 Hz |

| Power connection | 1-phase |

| Protection code | IP 30 |

| Power consumption | 100W |

| W x H x D closed | 205 x 155 x 520 mm |

| Net weight | ~19 kg |

| Standards | CE |

Please note:

*depending on feed material and instrument configuration/settings

"The XRD-Mill McCrone carries out size reduction mainly by friction. 48 cylindrical grinding elements are placed into the grinding jar in eight rows of six elements each.

During operation, the jar’s circular motion causes the elements to grind the sample from < 0.5 mm to the low μm-range (typically < 10 μm).

Thanks to the very gentle size reduction process, the crystal lattice of the sample is preserved. This makes the XRD-Mill McCrone the instrument of choice for the sample preparation for subsequent X-ray diffraction analysis." (RETSCH)

For additional details regarding this equipment, please visit http://www.retsch.com/products/miling/ball-mills/mccrone-xrd-mill to download the product brochure and data sheet.