Call us at 732 292-1994 or 800 867-6690 | Email us at triadscientific@gmail.com | Visite us on

PLANET BEST

Lab Instrumentation

Lab Equipment

Lab Furniture

16709

Mills >> 16709

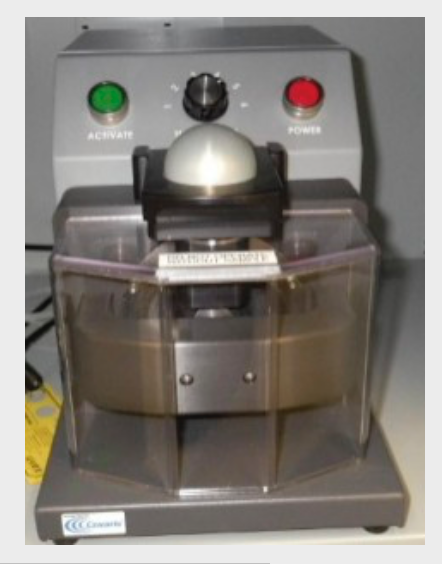

Retsch Jaw Crusher BB 100 Retsch Mill NEW

"The Jaw Crusher BB 100 is used for the rapid, effective crushing and pre-crushing of medium-hard, hard, brittle and tough materials.

Its variety of materials offered including heavy-metal free steel, its efficiency and safety makes this Jaw Crusher ideal for sample preparation in laboratories and industrial plants." (RETSCH)

Application Examples:

alloys, basalt, cement clinker, ceramics, chamotte, coal, coke, construction materials, feldspar, glass, granite, minerals, ores, oxide ceramics, quartz, rocks, silicon, slag, ... continue to application database

Product Advantages:

excellent crushing performance

wide range of materials for contamination free grinding

wear compensation with zero-point adjustment

continuous gap width setting

overload protection

no-rebound feed hopper with quick-release clamp

brake motor with safety switch

easy-to-clean crushing chamber

continuous grinding

connector for dust extraction

Features

| Applications | coarse and pre-crushing |

| Field of application | chemistry / plastics, construction materials, engineering / electronics, environment / recycling, geology / metallurgy, glass / ceramics |

| Feed material | medium-hard, hard, brittle, tough |

| Size reduction principle | pressure |

| Material feed size* | < 50 mm |

| Final fineness* | < 4 mm |

| Material of grinding tools | manganese steel, stainless steel, tungsten carbide, steel 1.1750 (for heavy-metal free grinding) |

| Jaw width | 60 x 60 mm |

| Gap width setting | 0 - 20 mm |

| Gap width display | scale |

| Zero point adjustment | yes |

| Hinged hopper | yes |

| Dust extraction unit | yes |

| Central lubrication | - |

| Process line version | - |

| Collector capacity | 2 l |

| Drive | 1-phase motor / 3-phase motor |

| Drive power | 0.75 kW |

| Electrical supply data | different voltages |

| Power connection | 1-phase / 3-phase |

| Protection code | IP 54 |

| W x H x D closed | 320 x 960 x 800 mm |

| Net weight | ~ 137 kg |

| Remark weight (without hopper etc.) | 0.75 kW |

| Standards | CE |

Please note:

*depending on feed material and instrument configuration/settings

"The BB 100 is a robust and powerful forced-feed Jaw Crusher. The feed material passes through the no-rebound hopper and enters the crushing chamber. Size reduction takes place in the wedgeshaped area between the fixed crushing arm and one moved by an eccentric drive shaft. The elliptical motion crushes the sample which then falls under gravity.

As soon as the sample is smaller than the discharge gap width, it falls into a removable collector within the Jaw Crusher. The continuous gap width setting with scale ensures optimum size reduction in accordance with the set gap width." (RETSCH)

For additional details regarding this equipment, please visit http://www.retsch.com/products/miling/jaw-crusher/bb-100/ to download the product brochure and data sheet.