Call us at 732 292-1994 or 800 867-6690 | Email us at triadscientific@gmail.com | Visite us on

PLANET BEST

Lab Instrumentation

Lab Equipment

Lab Furniture

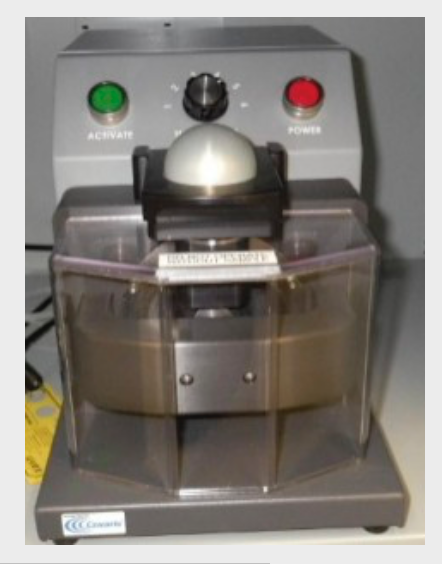

Retsch Drum Mill TM 300 XL Retsch Mill NEW PRODUCT

Mills >> Retsch Drum Mill TM 300 XL Retsch Mill NEW PRODUCT

Retsch Drum Mill TM 300 XL Retsch Mill NEW

"The TM 300 XL Drum Mill is used for the preparation of granules and powders. The grinding process is performed either in dry or wet conditions. The drum mill can be operated either as a Ball or as a Rod Mill by using the corresponding module. A sufficient number of balls or rods is required for an effective grinding process. Typically, a final fineness below 150 microns is obtained.

The mill consists of a gear motor mounted on a solid steel frame complete with outlet funnel and a set of separation screens plus sample collector. The TM 300 XL features a yoke and locking mechanism for easy access to the sample. The drum cover is easily removed for cleaning thanks to a quick release locking mechanism.

Adjustment of grinding parameters:

Parameters like grinding time or start and stop are set conveniently via the display. The following factors have an influence on the final particle size: Sample characteristics, maximum feed size and capacity. We will gladly support you in working out the most suitable configuration for your specific application." (RETSCH)

Application Examples:

alloys, bentonite, bones, carbon fibres, catalysts, cellulose, cement clinker, ceramics, charcoal, chemical products, clay minerals, coal, coke, compost, concrete, electronic scrap, fibres, glass, gypsum, hair, hydroxyapatite, iron ore, kaolin, limestone, metal oxides, minerals, ores, paints and lacquers, paper, pigments, plant materials, polymers, quartz, seeds, semi-precious stones, sewage sludge, slag, soils, tissue, tobacco, waste samples, wood, ...

Product Advantages:

powerful and quick grinding of large quantities

suitable for dry and wet grinding

variable speed, reproducible results

suitable for long-term operations

ball mill and rod mill modules available

easy tilt to empty the grinding jar

solid steel frame

removable sample collector

convenient parameter setting via display

standard sizes of grinding drums from 5 to 43.4 l

separation grid to separate sample from grinding balls (only for Ball Mill)

funnel with handles

guide rail allows for ergonomic removal of drum

grinding jar with gasket for lossfree operation

solid noise-protection hood

emergency switch

Features

| Applications | pulverizing, mixing |

| Field of application | agriculture, biology, Chemistry, construction materials, engineering / electronics, environment / recycling, geology / metallurgy, glass / ceramics, medicine / pharmaceuticals |

| Feed material | soft, hard, brittle, fibrous - dry or wet |

| Size reduction principle | friction |

| Material feed size* | < 20 mm |

| Final fineness* | < 20 µm |

| Batch size / feed quantity* | minimum 1 l / maximum 20 l |

| Rotation speed | 0 - 80 min-1 |

| No. of grinding stations | 1 |

| Material of grinding tools | hardened steel |

| Grinding drum sizes | 5 l / 10 l / 21.7 l / 43.3 l |

| Setting of grinding time | digital |

| Drive | 3-phase asynchronous motor with frequency converter |

| Drive power | 0.75 kW |

| Electrical supply data | different voltages |

| Power connection | 1-phase |

| Protection code | IP 50 |

| Power consumption | ~ 750 W (VA) |

| W x H x D closed | 1500 x 1200 x 700 mm |

| Net weight | ~ 295 kg |

| Standards | CE |

Please note:

*depending on feed material and instrument configuration/settings

"In a drum mill the sample (usually pre-crushed material) is placed inside the drum with the grinding media (grinding balls or rods) and subjected to external forces. The Ball Mill and Rod Mill Modules are used for fine grinding of solid matter by impact and friction, in wet or dry condition. The drum, which contains the sample and grinding balls or rods, rotates around a horizontal axis. Whereas particles break more easily when larger grinding ball resp. rod diameters are used, smaller diameters lead to a substantially higher final fineness.

The motor incorporates a solid-state controller with internal overload protection which is used to set and accurately control different drum speeds." (RETSCH)

For additional details regarding this equipment, please visit http://www.retsch.com/products/miling/ball-mills/tm-300-xl/ to download the product brochure and data sheet.