Call us at 732 292-1994 or 800 867-6690 | Email us at triadscientific@gmail.com | Visite us on

PLANET BEST

Lab Instrumentation

Lab Equipment

Lab Furniture

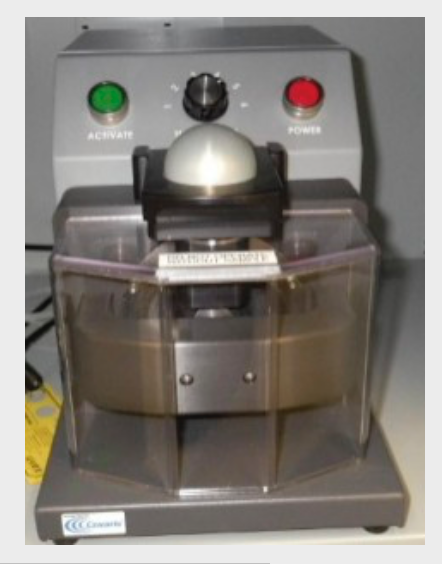

Retsch Vibratory Disc Mill RS 200 Retsch Mill NEW

Mills >> Retsch Vibratory Disc Mill RS 200 Retsch Mill NEW

Retsch Vibratory Disc Mill RS 200 Retsch Mill NEW

"The Vibratory Disc Mill RS 200 is suitable for the extremely quick, loss-free and reproducible grinding of medium-hard, brittle and fibrous materials to analytical fineness. The instrument runs steadily and smoothly, even with heavy grinding sets, at maximum speed thanks to the new Stabilized-Plane-Drive.

With its robust design, the RS 200 has proven to be ideal for use in the building materials sector (cement), in geology, mineralogy, metallurgy and in power plants. Due to the high end fineness and speed the RS 200 is the perfect mill when it comes to preparing samples for spectral analysis." (RETSCH)

Application Examples:

cement, cement clinker, ceramics, coal, coke, concrete, corundum, electronic components, glass, metal oxides, minerals, ores, plant materials, silicates, slag, soils, ... continue to application database

Product Advantages:

reproducible results due to "Stabilized-Plane-Drive" (avoids tumbling of the grinding set)

variable speed 700 - 1,500 min-1

extremely short grinding time

agate and tungsten carbide recognition for automatic speed reduction

10 SOPs can be stored

no sample loss thanks to optimum o-ring seal

wide range of materials for contamination free grinding

noise-insulated grinding chamber

new quick-action grinding set clamping device for convenient and safe tightening

safety interlock

easy 1-button operation with colored graphics display

new carry handle

new ergonomic design, heavy grinding sets can be inserted closer to the user´s body and slided into the machine, leading to less strenuous laboratory work especially for high throughput users

Features

| Applications | size reduction, mixing, triturating |

| Field of application | construction materials, environment / recycling, geology / metallurgy, glass / ceramics |

| Feed material | medium-hard, hard, brittle, fibrous |

| Size reduction principle | pressure, friction |

| Material feed size* | < 15 mm |

| Final fineness* | < 20 µm |

| Batch size / feed quantity* | 15- 250 ml depending on size of grinding set |

| Speed at 50 Hz (60 Hz) | 700 - 1,500 min-1, continuously adjustable |

| Material of grinding tools | hardened steel, tungsten carbide, agate, zirconium oxide, steel 1.1740 (for heavy-metal free grinding) |

| Grinding jar sizes | 50 ml / 100 ml / 250 ml |

| Setting of grinding time | digital, 00:01 to 99:59 |

| Storable SOPs | 10 |

| Drive | 3-phase asynchronous motor with frequency converter |

| Drive power | 1.5 kW |

| Electrical supply data | different voltages |

| Power connection | 1-phase |

| Protection code | IP 40 |

| W x H x D closed | 836 x 1220 x 780 mm |

| Net weight | ~ 210 kg (without grinding set) |

| Standards | CE |

Please note:

*depending on feed material and instrument configuration/settings

"The Vibratory Disc Mill RS 200 comminutes by impact and friction. The grinding set is firmly attached to the vibration plate with a quick-action lever. The plate with the grinding set is subjected to circular horizontal vibrations.

The centrifugal force acting on the grinding rings in the dish results in extreme pressure, impact and frictional forces acting on the sample, producing analytical fineness in 1-3 minutes. The circular vibrations are produced by a frequency controlled 1.5 kW 3-phase motor.

A sensor recognizes the presence of agate grinding sets and automatically limits the speed to 700 min-1 to avoid damaging the agate. The cover of the noiseinsulated grinding chamber has a safety interlock and can only be opened when the mill is at a standstill." (RETSCH)

For additional details regarding this equipment, please visit http://www.retsch.com/products/miling/disc-mills/rs-200/ to download the product brochure and data sheet.