Call us at 732 292-1994 or 800 867-6690 | Email us at triadscientific@gmail.com | Visite us on

PLANET BEST

Lab Instrumentation

Lab Equipment

Lab Furniture

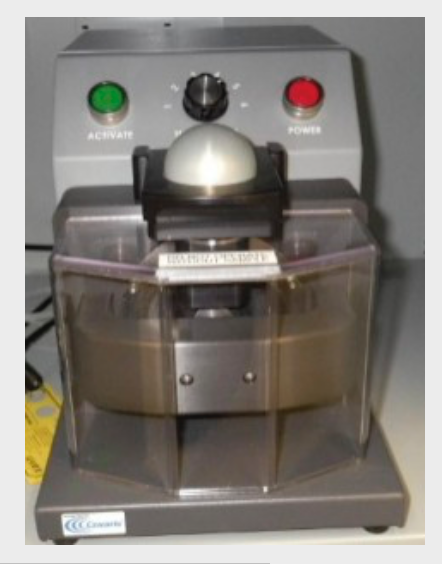

Retsch Rotor Beater Mill SR 300 Retsch Rotor Mill NEW

Mills >> Retsch Rotor Beater Mill SR 300 Retsch Rotor Mill NEW

Retsch Rotor Beater Mill SR 300 Retsch Rotor Mill NEW

"The Rotor Beater Mill SR 300 is suitable for coarse and fine size reduction, either in batches or continuously. It can process dry, soft, medium-hard, organic and inorganic substances.

With its adjustable speed of 3,000 to 10,000 rpm the rotor beater mill SR 300 is intended for universal use: from sample preparation in laboratories up to preparing sample batches in pilot plants or production facilities. The grinding chamber, the feed hopper and the material inlet are completely made from high quality stainless steel." (RETSCH)

Application Examples

bentonite, chemical products, coal, coke, drugs, feed pellets, fertilizers, food, graphite, gypsum, herbs, pharmaceutical materials, plant materials, plastics, powder coating, resins, rice, salts, seeds, soils, spices, sugar, ... continue to application database

Product Advantages

- suitable for batchwise operation of larger quantities

- high final fineness

- adjustable speed for different applications

- easy cleaning thanks to exchangeable push-fit grinding insert, rotor and cassette

- grinding chamber, feed hopper and material inlet and outlet of stainless steel

- optional grinding inserts 180° for grinding of hard-brittle materials by additional impact

- optional distance rotor to reduce frictional heat

- removable hopper for easy cleaning

- electric engine brake

- defined final fineness due to bottom sieves with aperture sizes from 0.08 - 10 mm

- central locking device

- wide range of accessories including various collection and feeding systems, rotors and sieves

Features

| Applications | size reduction, deagglomeration |

| Field of application | agriculture, chemistry / plastics, construction materials, environment / recycling, food, geology / metallurgy, medicine / pharmaceuticals |

| Feed material | soft, medium-hard |

| Material feed size* | < 25 mm |

| Final fineness* | < 50 µm |

| Speed at 50 Hz (60 Hz) | 3,000 - 10,000 min-1 (in steps of 500 min-1) |

| Rotor peripheral speed | 22 ..72 m/s |

| Types of rotors | standard / distance |

| Material of grinding tools | rotor and sieves of stainless steel |

| Sieve sizes | trapezoid holes 0.08 / 0.12 / 0.20 / 0.25 / 0.35 / 0.50 / 0.75 / 1.00 / 1.25 / 1.50 / 2.00 mm round holes 3.00 / 4.00 / 10.00 mm |

| Hinged hopper | removeable hopper |

| Dust extraction unit | optional cyclone |

| Collector capacity | 5 l / optional: 30 l |

| Drive | 3-phase motor |

| Electrical supply data | 200 .. 240 V |

| Power connection | 1-phase |

| Engine brake | yes, electric |

| Protection code | IP 41 |

| Power consumption | 2.5 kW |

| W x H x D closed | 600 x 1200 x 700 mm (with base frame) |

| Net weight | ~ 60 kg (with base frame) |

| Standards | CE |

Please note:

*depending on feed material and instrument configuration/settings

"Size reduction and deagglomeration in the SR 300 are achieved by impact and shear effects.The feed material passes from the hopper into the center of the grinding chamber where it is crushed between the rotor, sieve and grinding inserts.

As soon as the material is smaller than the aperture size of the sieve it enters the collecting receptacle. The quick-acting door lock ensures easy access to the grinding chamber for quick cleaning. With their safety switch, splashback and access barrier in the inlet and outlet areas, Rotor Beater Mills offer the highest degree of operating safety." (RETSCH)