PLANET BEST

Lab Instrumentation

Lab Equipment

Lab Furniture

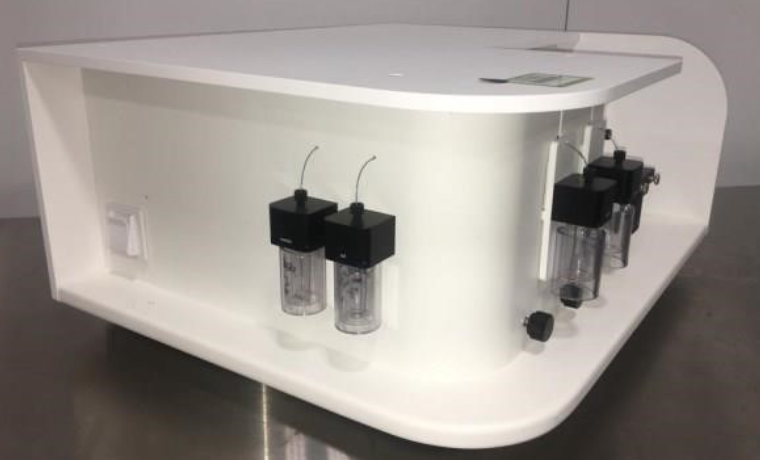

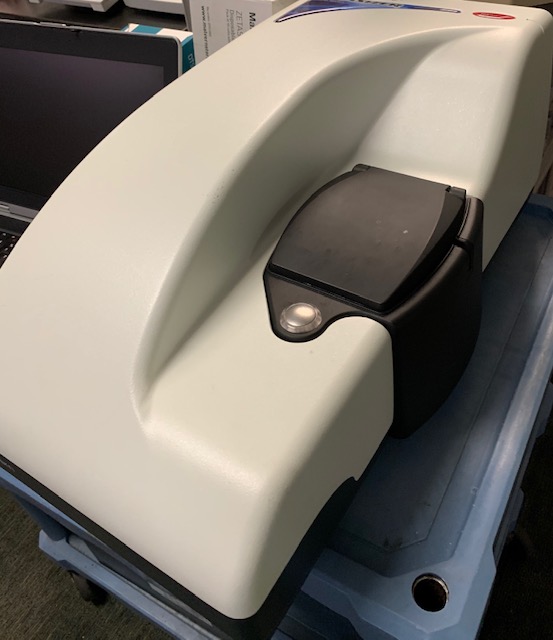

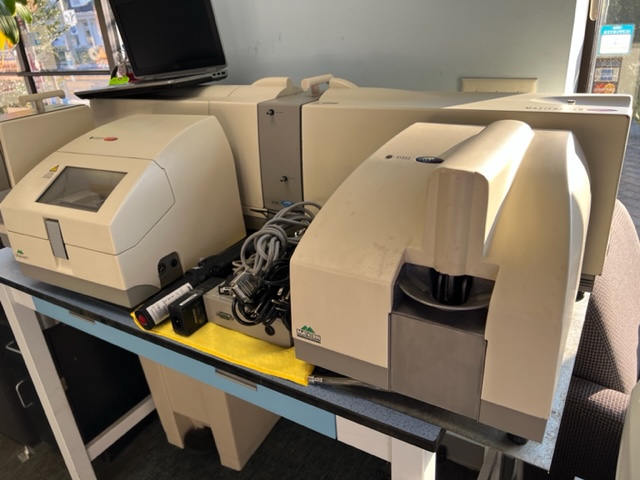

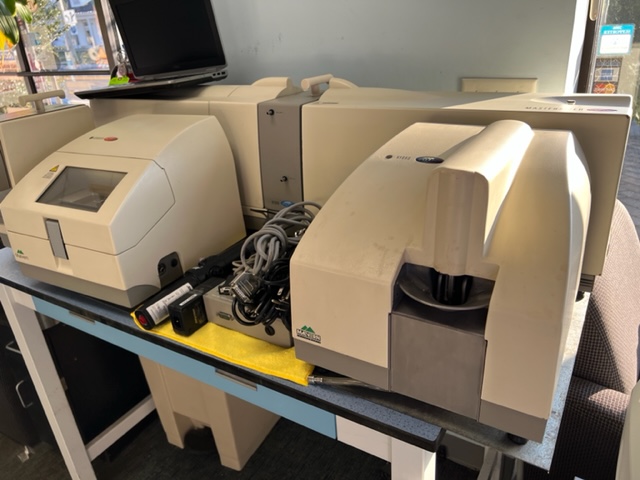

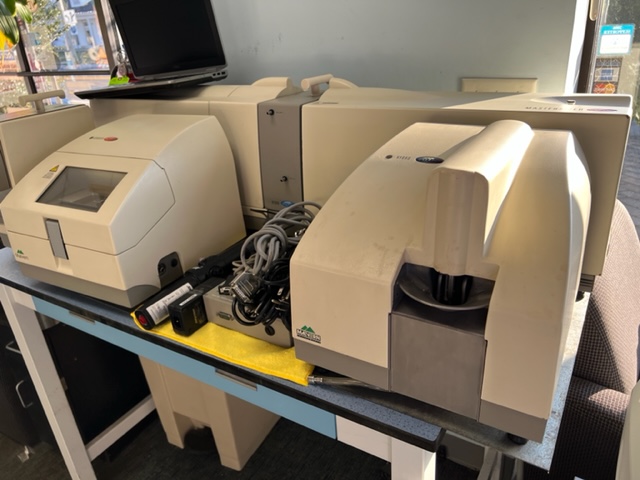

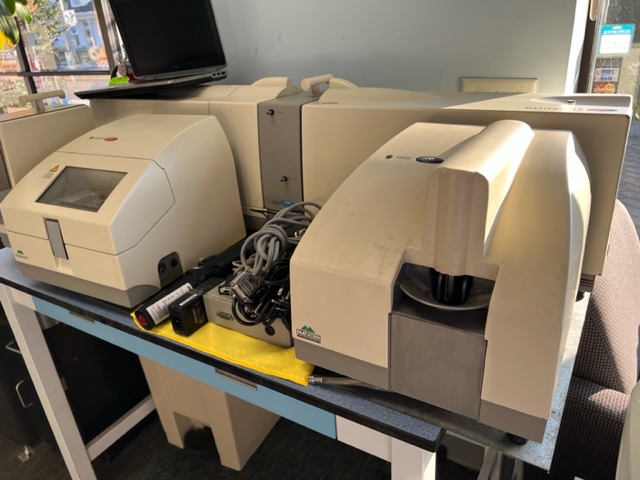

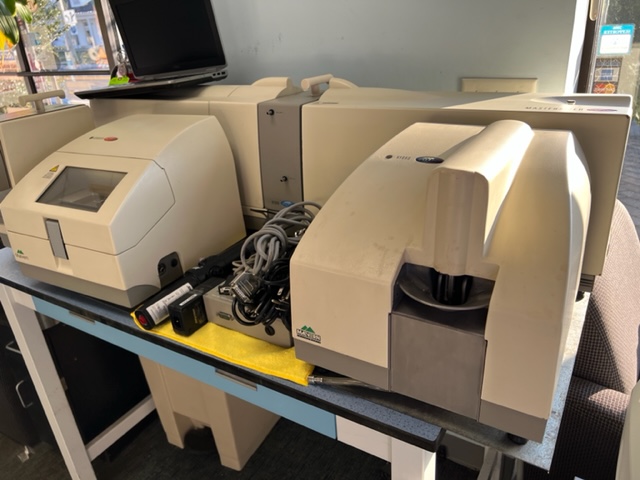

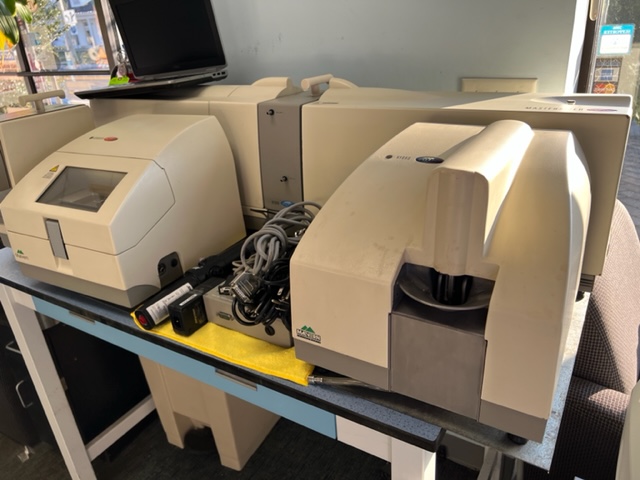

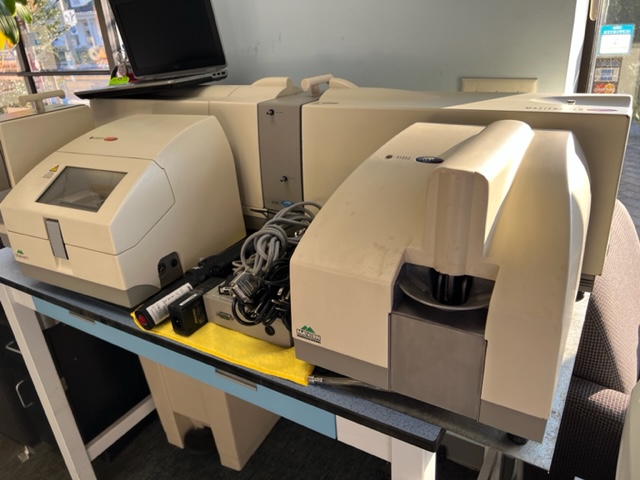

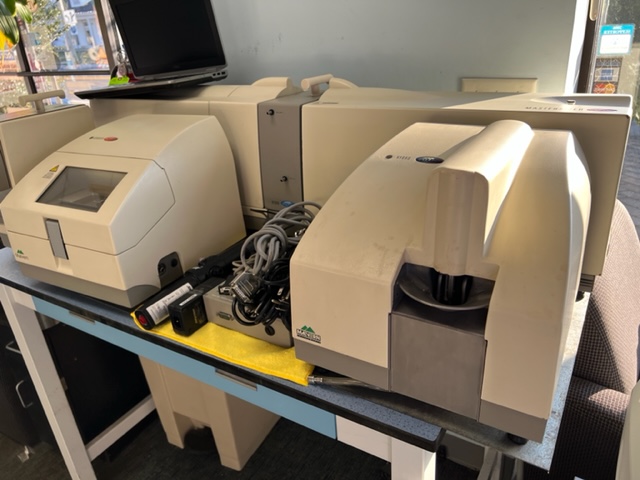

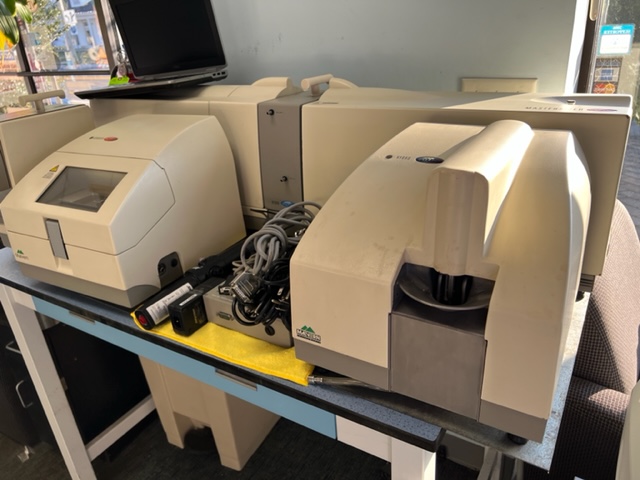

Retsch Air Jet Sieving Machine AS 200 jet Retsch Sieve NEW

Particle Size Analysis >> Retsch Air Jet Sieving Machine AS 200 jet Retsch Sieve NEW

Retsch Air Jet Sieving Machine AS 200 jet Retsch Sieve NEW

"The new Air Jet Sieve AS 200 jet is particularly suitable for sieve cuts of powdered materials which require efficient dispersion and desagglomeration. The option to store up to 10 SOPs and the automatic vacuum regulator (accessory) guarantees reproducible and meaningful results.

Innovative features such as the Open Mesh function, the selection of the nozzle speed as well as optional use of standard 2" high test sieves perfects the new air jet technology." (RETSCH)

Application Examples:

ceramics, chemical products, cosmetics, food, minerals, pharmaceutical materials, pigments, plastics, powder coating, rubber, toner, washing powder, ...

Product Advantages:

sieving with air jet technology for dispersion and desagglomeration of fine powders

Open Mesh Function to reduce the number of near-mesh particles

high flexibility through adjustable nozzle speed

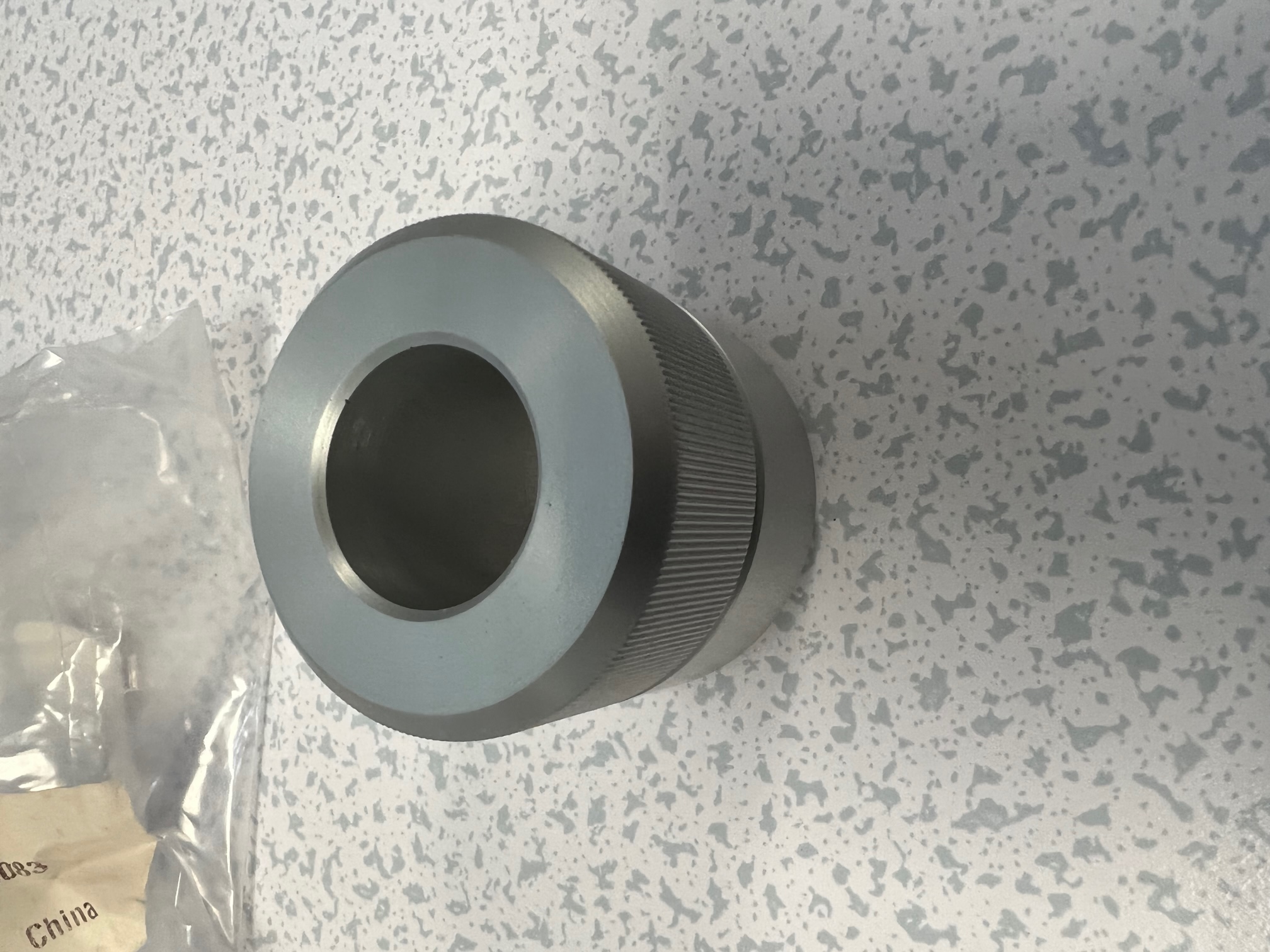

operation with standard Retsch sieves, 203 mm (8")Ø or 200 mm Ø (with adapter), 1" or 2" high

free manual (standard) or automatic (accessory) pressure regulation

optional software EasySieve for control through RS232 serial interface, easy evaluation and documentation of results

free digital adjustment of all process parameters (time, vacuum, speed)

additional Quick Start mode

silent operation due to integrated silencer

collection of two fractions possible by use of cyclone

air jet produced by a powerful industrial vacuum cleaner

fulfils all criteria for measuring equipment related to ISO 9001

easy operation, ergonomic design

maintenance-free

memory for up to 9 SOPs

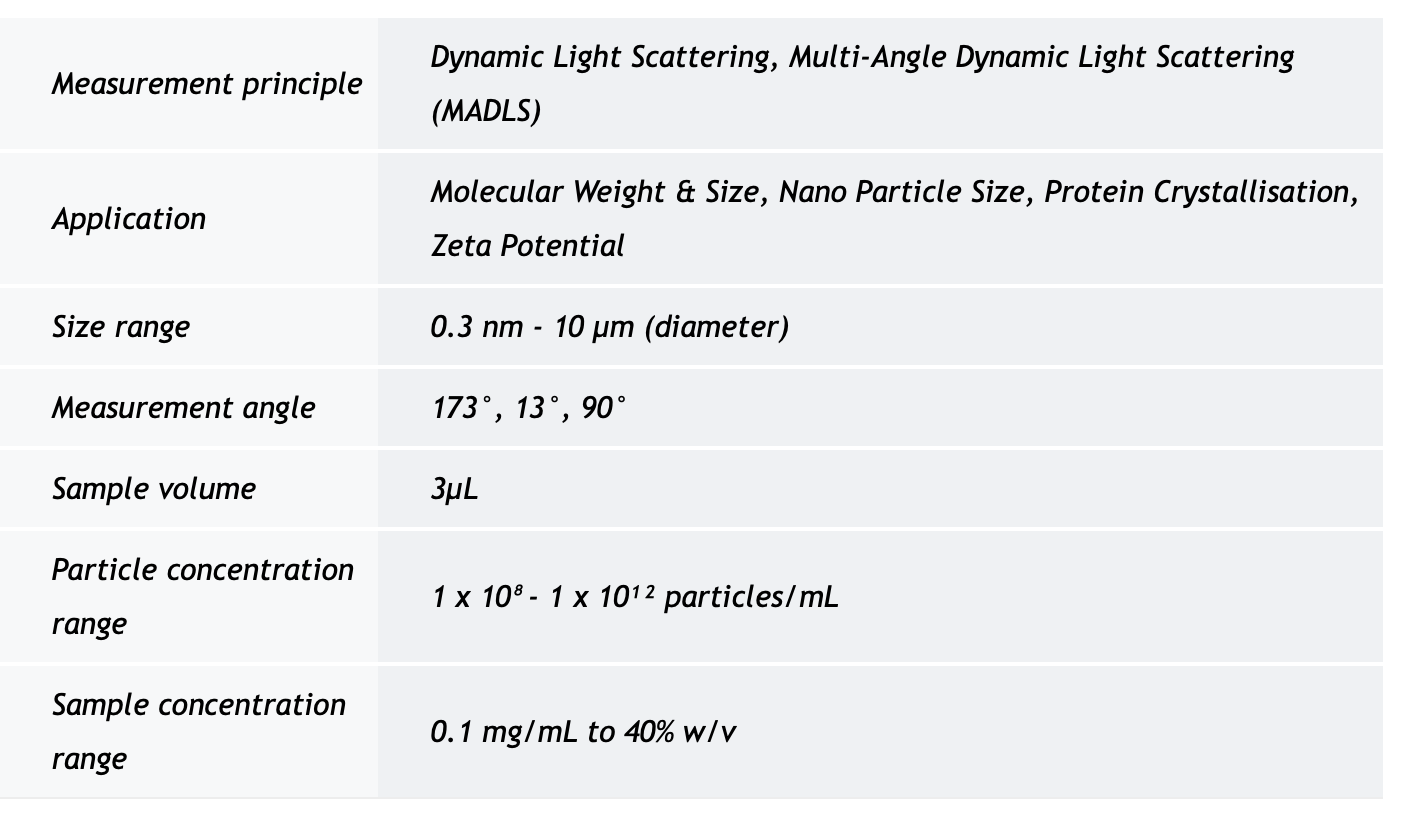

Features

| Applications | separation, fractioning, particle size determination |

| Field of application | chemistry / plastics, construction materials, environment / recycling, food, geology / metallurgy, glass / ceramics, medicine / pharmaceuticals |

| Feed material | powders |

| Measuring range* | 10 µm - ~ 4 mm |

| Sieving motion | dispersion by air jet |

| Max. batch / feed capacity | 0.3 - 100 g |

| Max. number of fractions | 1 (by using a cyclone: 2) |

| Speed | digital, 5 - 55 min-1 (nozzle) |

| Time display | digital, 00:01 - 99:59 min |

| Interval operation | - |

| Vacuum | 2,000 - 9,999 Pa / 20 - 99 mbar / 0.3 1.45 psi |

| Storable SOPs | 9 / Quick Start mode |

| Suitable for dry sieving | yes |

| Suitable for wet sieving | - |

| Serial interface | yes |

| Including test certificate / can be calibrated | yes |

| Suitable sieve diameters | 203 mm (200 mm with adapter) |

| Max. height of sieve stack | 1 sieve (25 mm (1") / 50 mm ( 2")) |

| Accessories | cyclone / automatic vacuum regulation |

| Electrical supply data | 100-240 V, 50/60 Hz |

| Power connection | 1-phase |

| W x H x D | 460 x 288 x 305 (without cover) |

| Net weight | ~ 14 kg |

| Standards | CE |

Please note:

*depending on feed material and instrument configuration/settings

"The AS 200 jet is equipped with a rotating slotted nozzle. The sieve and lid are placed above the nozzle. A vacuum generates a strong jet of air which disperses the particles on the sieve through the slotted nozzle. The material which is smaller than the mesh size of the sieve is transported by the back flow of the air to the cyclone or to the vacuum cleaner. The air jet helps to deagglomerate the particles and constantly purges the sieve mesh." (RETSCH)

For additional details regarding this equipment, please visit http://www.retsch.com/products/sieving/sieve-shakers/as-200-jet/ to download the product brochure and data sheet.