PLANET BEST

Lab Instrumentation

Lab Equipment

Lab Furniture

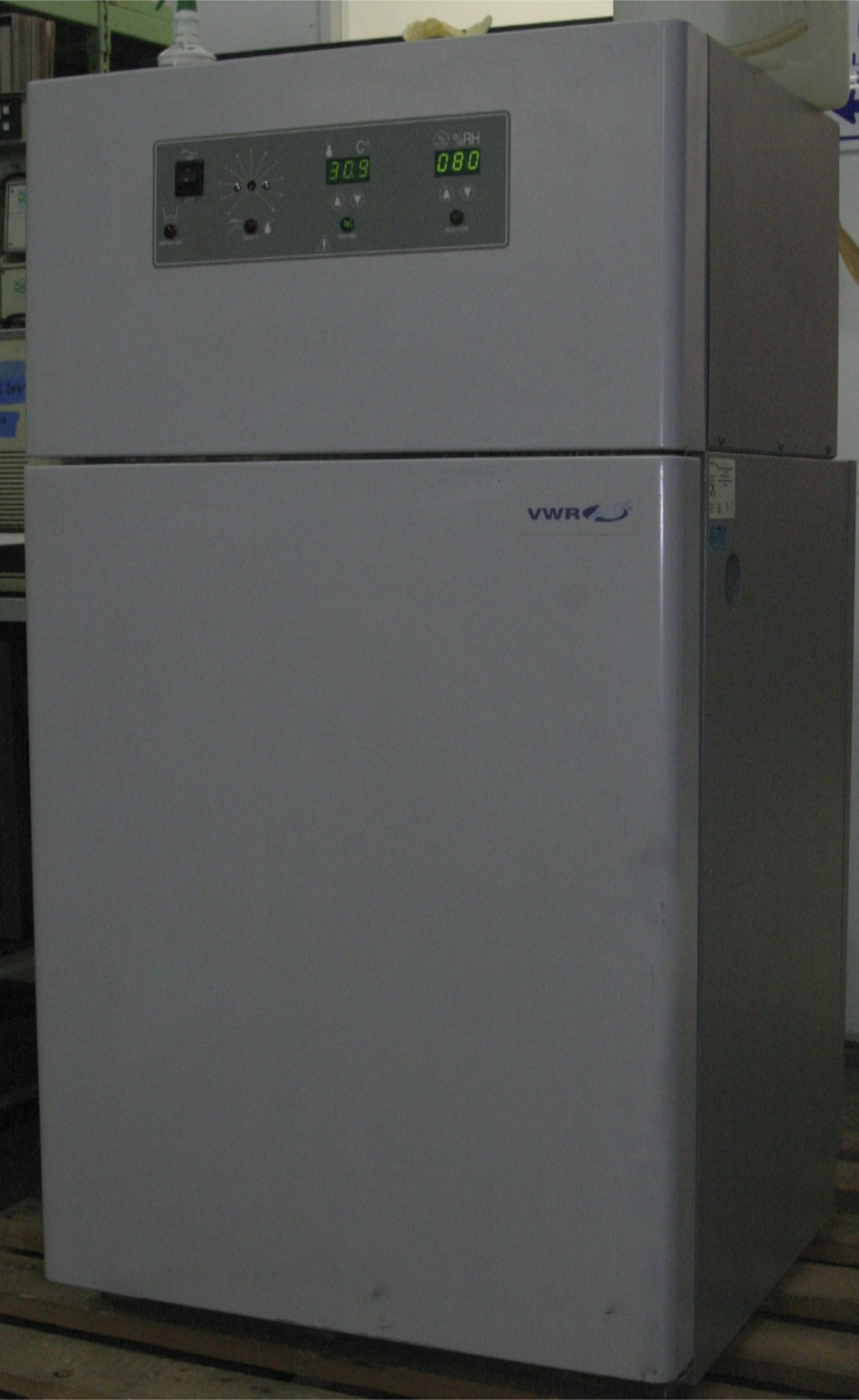

Thermo Forma 3911 Environmental Chamber Thermo 3911 Environmental Chamber Thermo Forma 3911 Stability Chamber Thermo 3911 Sta

Chambers Temperature Humidity Stability >> Thermo Forma 3911 Environmental Chamber Thermo 3911 Environmental Chamber Thermo Forma 3911 Stability Chamber Thermo 3911 Stability Chamber Thermo Forma 3911 Environmental Chamber Thermo 3911 Environmental Chamber Thermo Forma 3911 Temperature Humidity Ch

Thermo Forma 3911 Environmental Chamber Thermo 3911 Environmental Chamber Thermo Forma 3911 Stability Chamber Thermo 3911 Stability Chamber Thermo Forma 3911 Environmental Chamber Thermo 3911 Environmental Chamber Thermo Forma 3911 Temperature Humidity Chamber Thermo 3911 Temperature Humidity Chamber used real nice

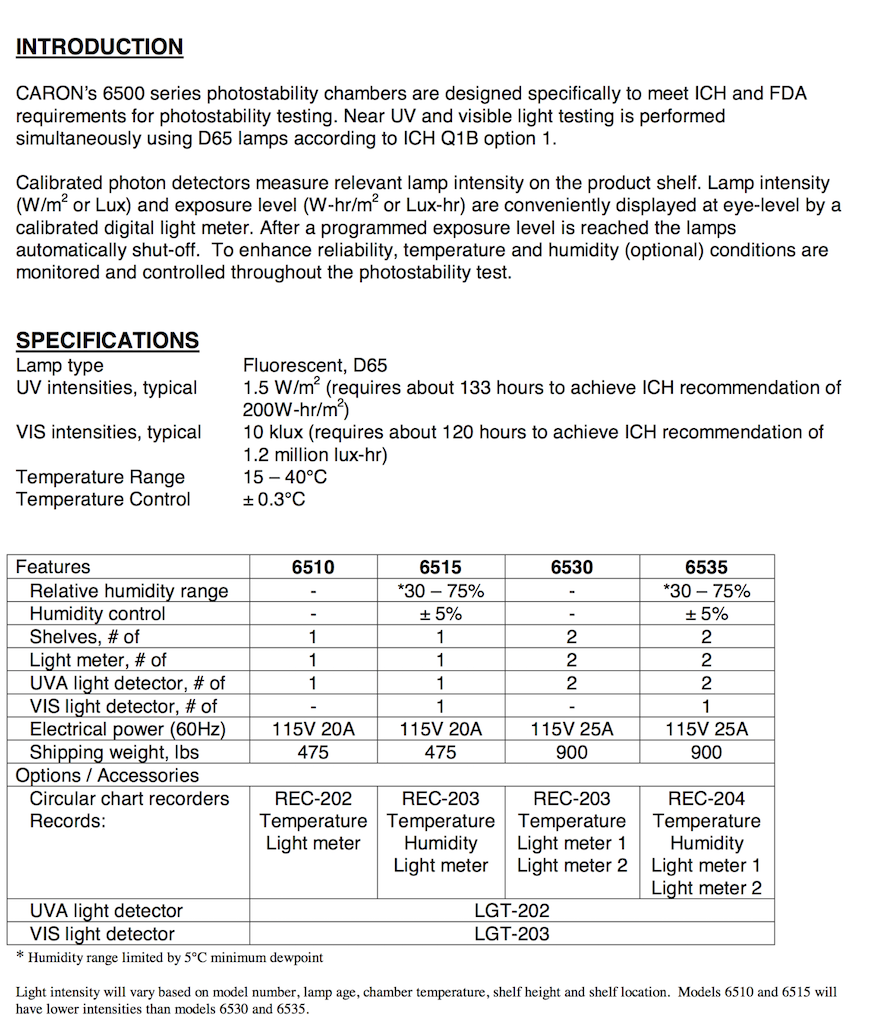

These high precision cabinets meet ICH, FDA, TAPPI, ASTM, and other national testing standards.

Meets International Conference on Harmonization (ICH) guidelines for drug substance and product storage testing

Ideal for drug stability studies, shelf life testing for packaged products, and insect and other large-scale biological research

Temp Range 0°C to 60°C

Relative Humidity : Above ambient to 95% @ 37°C (98.6°F) ±5.0% RH

Control: ±0.1°C @ 25°C to 37°C (77°F to 98.6°F)

Sensor Type: RTD

Microprocessor PID controller which is programmable with 24 Ramp and Soak Steps

Digital Dual LED display can be read and set in 0.1°C increments; one digital setpoint

Audible and Visual high/low temperature alarms

Refrigeration is accomlished by a 1/4 HP, air-cooled compressor and Non-CFC, R134A refrigerant

Fittings include a drain port on the bottom - 3/8" FPT and 3/8" O.D. P-trap right rear; Fill Port - 1/8" female NPT

Includes NEMA 14-20P Plug

Dry Contacts for Common, NO, NC

Standard 4 to 20 milliamp output connects to most alarm/monitoring systems, allowing you to meet internal and regulatory product documentation requirements

NOTE: Drain Required unless fitted with the optional Condensate Evaporator (Model 1900031)

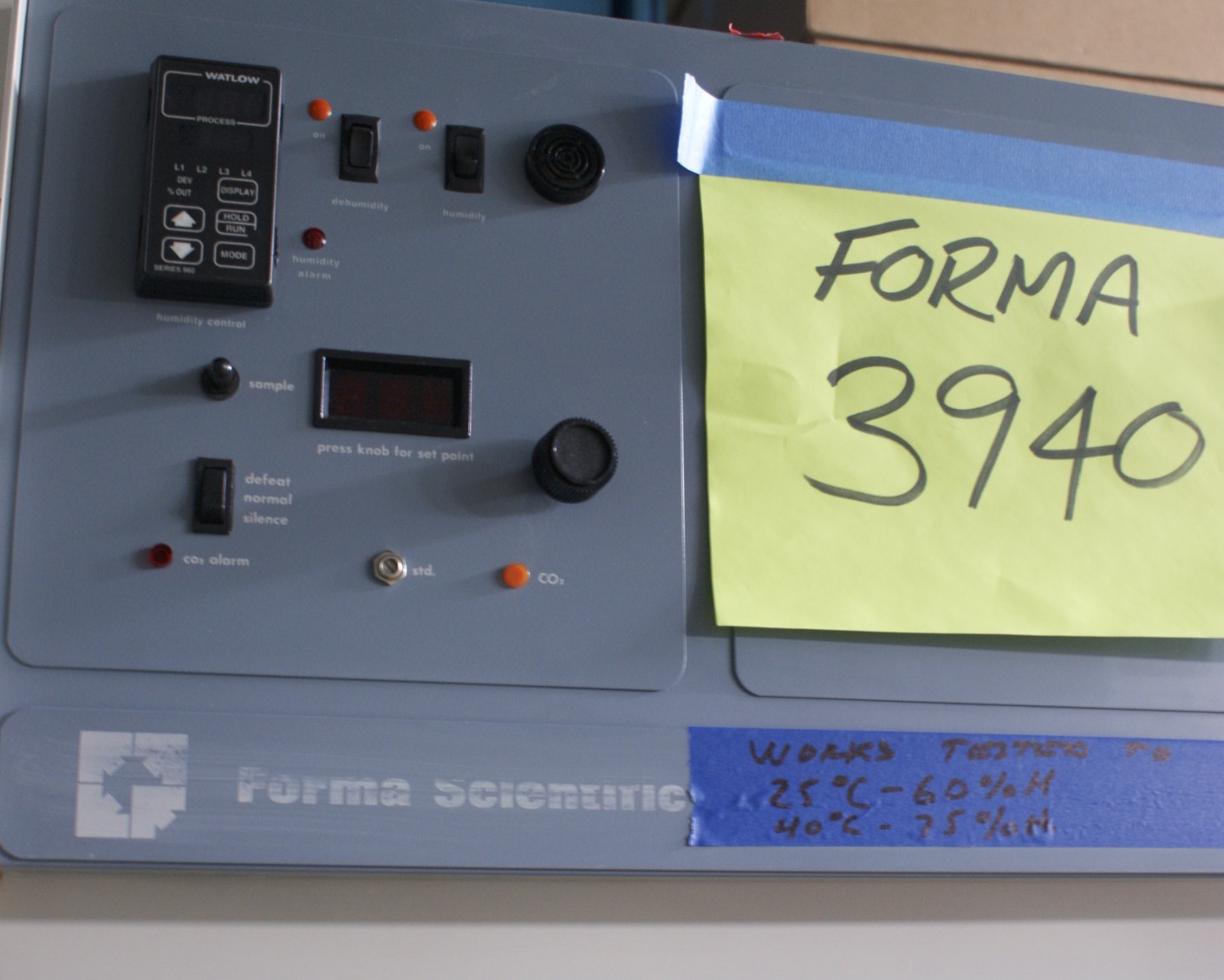

Humidity Control

Input Water Quality: 50K-1Megohm resistance

Input Water Volume: 1 gallon/hour

Input Water Pressure: Gravity to 40 psi

Sensor: Bulk polymer

Microprocessor PID controller which is programmable with 24 Ramp and Soak Steps

Setpoint: Digital (direct set in % RH)

Display: Digital, dual LED (direct read in % RH)

Readability and Setability: 1.0%

Steam Generator: Initial fill approx. 1 qt. (1 liter)

Audible and Visual Alarms

NOTE: This unit requires a constant water source

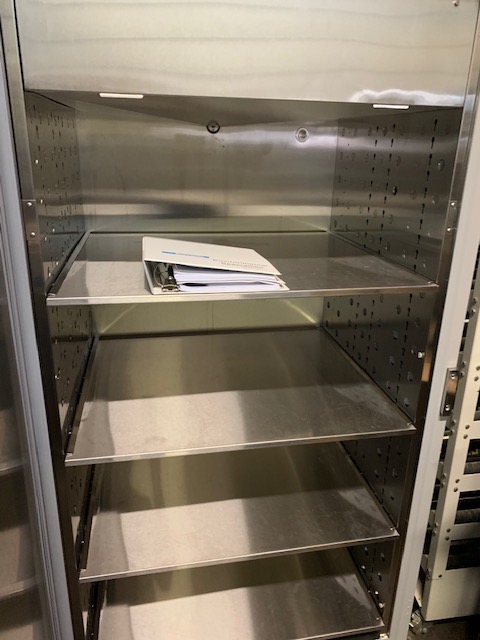

Directed Horizontal Laminar Airflow System

Horizontal Airflow

Directed airflow minimizes the risk of product desiccation and loss, and wasted time and money due to poor temperature uniformity and recovery

Promotes an ideal growth environment far surpassing the efficiency of a top-to-bottom, undirected airflow design

Includes a positive pressure feed plenum on the right side of the chamber and a negative pressure return plenum on the left to distribute the airflow uniformly throughout the chamber

Even when filled with samples or equipment, each shelf receives a consistent flow of conditioned air for optimum temperature uniformity and recovery.

Directed airflow prevents deterioration of temperature uniformity and recovery when shelves are full because airflow is not blocked

By design, the feed plenum cannot be blocked by the chamber's contents.