PLANET BEST

Lab Instrumentation

Lab Equipment

Lab Furniture

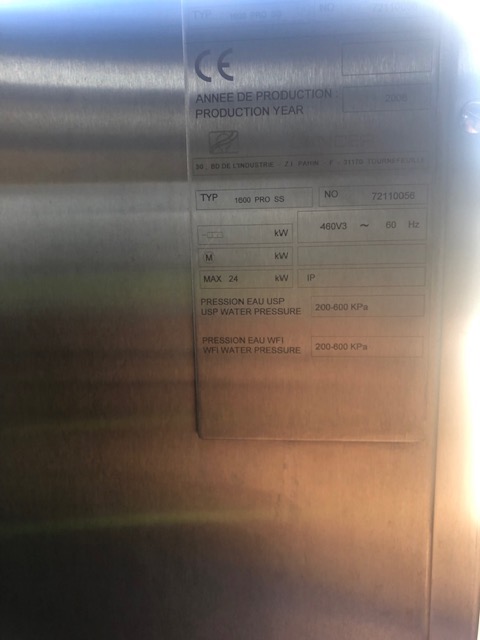

LANCER 1600 PRO SS Pharmaceutical Production Washer Lance Spindle Head Washer

Washers/ Glassware >> LANCER 1600 PRO SS Pharmaceutical Production Washer Lance Spindle Head Washer

LANCER 1600 PRO SS Pharmaceutical Production Washer LANCER 1600 PRO SS Pharmaceutical Production Washer Lance Spindle Head Washer with multiple level washing capabilities is manufactured to exceed all GMP requirements used

Information gathered from internet please confirm current applications-

LANCER 1600 PRO SS Pharmaceutical Production Washer with multiple level washing capabilities is manufactured to exceed all GMP requirements and has the following features and options:

Dimensions

Single door version:

Chamber Dimensions: 33.5"H x 27.75"W x 27.75"D

External Dimensions: 90.16"H x 47.64"W x 61.22"D

Double door version:

Chamber Dimensions: 33.5"H x 27.75"W x 27.75"D

External Dimensions: 90.16"H x 82.68"W x 36.02"D

Materials & Finishes

AISI 316L stainless steel chamber

1" radius corner chamber

Chamber polished Ra 0.6mm

AISI 316L stainless steel drop down door

AISI 304 stainless steel frame

AISI 316L stainless steel external panels

Chamber and panels insulated with "particle-free", non-chloride insulation

Hinged or removable maintenance access doors

3-A rated 316L stainless steel wash pump

AISI 316L stainless steel pipes, 1% slope minimum

Orbital welded piping, internal finish 0.6 mm Ra (excluding weld)

Connections via 316L stainless steel Tri-clamps (no threads)

AISI 316L stainless steel, pneumatically activated piston valves

Pneumatically actuated Sanitary Diaphragm valves

Drying System

Injection of hot filtered air into chamber (for drying outside of items)

Injection of hot filtered air into hydraulic circuit (for drying inside of items)

Pre-filter located upstream of drying components

HEPA filters located downstream of all drying components

Drying temperature, adjustable up to 110°C

HEPA filter loading alarm via a differential pressure switch

Magnehelic gauge for viewing of HEPA loading (OPTIONAL)

DOP Ports for HEPA filter integrity testing

Safety Features

Pneumatic door locking during the cycle cool down phase

Interlocking doors (on double-door models)

Cleaning Chemicals

2 peristaltic pumps (standard)

Additional peristaltic pumps (OPTIONAL)

Liquid level detection

Verification of chemical addition via Conductivity meters (OPTIONAL) or pressure transmitters (OPTIONAL)

Control Systems

LANCER Controls

LANCER Programmable microprocessor, 2-line display interface

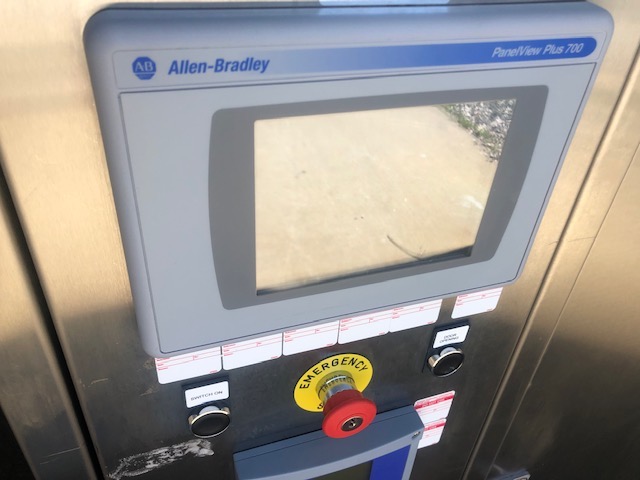

Allen Bradley Controls (OPTIONAL)

Allen Bradley SLC 5/04 industrial Programmable Logic Controller (PLC), PV 600 color touch screen, DH communications (OPTIONAL)

Allen Bradley SLC 5/05 industrial Programmable Logic Controller (PLC), with Ethernet connection, PV 600 color touch screen (OPTIONAL)

"PACK " for Allen Bradley PLC: (OPTIONAL)40-column built in printer

Hydraulic circuit pressure sensor

2 pressure sensors for monitoring of chemical addition

RS-232 output port (if controlled by microprocessor)

Validation monitor (OPTIONAL)Monitoring of final rinse conductivity (OPTIONAL)

Separate temperature probes

Hydraulic circuit pressure sensor

2 pressure sensors controlling chemical dispensing

Monitoring of wash solution conductivity (OPTIONAL)

Sampling port and sampling valve (OPTIONAL)

Cycle Configuration

User-programmable, password protected cycle parameters (temperature, times, cycle phases)

Number of rinses programmable

Single pass final rinse (OPTIONAL)

Documentation

Complete validation documentation including IQ/OQ protocols (FAT, SAT), roughness and weld certificates

Material conformity declaration

Fully traceable material certificates (OPTIONAL)

Utilities

Cold water supply

Hot water supply

Water supply, purified/USP/WFI

Loop actuation (WFI) (OPTIONAL)

Steam heating

Electric heating (OPTIONAL)

Compressed air

Gravity drain

Steam chimney

Butterfly valve on steam chimney (OPTIONAL)

Inspections

Electrical inspection by an independent agency (OPTIONAL)

Hydraulic test on steam coil by an independent agency (OPTIONAL)