PLANET BEST

Lab Instrumentation

Lab Equipment

Lab Furniture

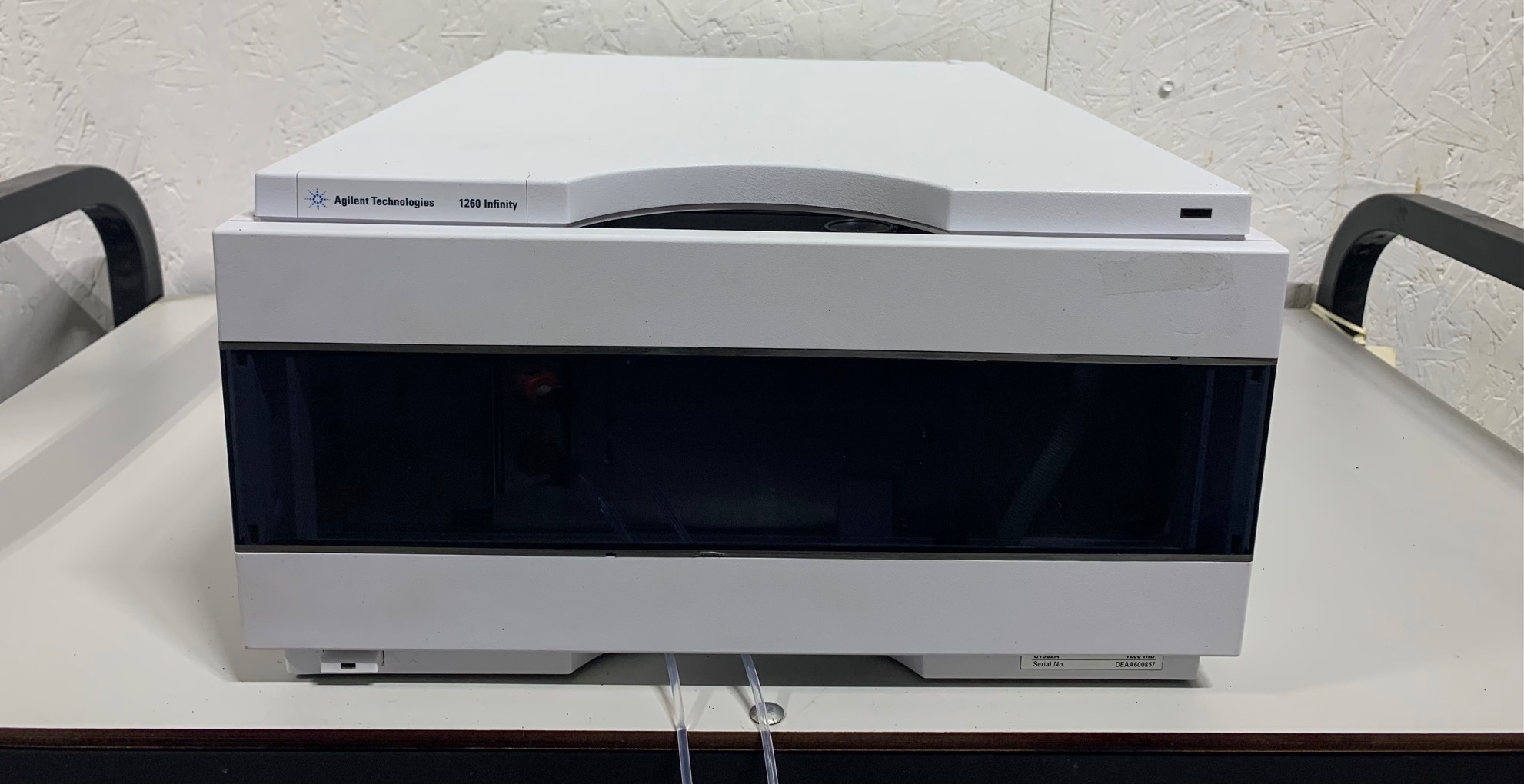

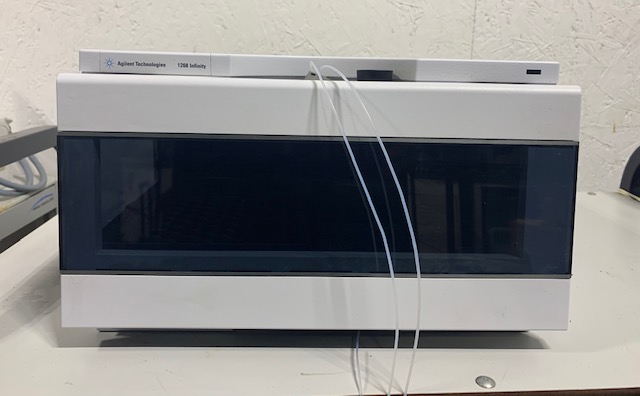

used Agilent G1364C Agilent 1260 infinity Fraction Collector / Agilent G1364C 1260 infinity Auto Sampler Agilent 1260 infinity Fraction Collector

HPLC Detectors >> used Agilent G1364C Agilent 1260 infinity Fraction Collector / Agilent G1364C 1260 infinity Auto Sampler Agilent 1260 infinity Fraction Collector

used Agilent G1364C Agilent 1260 infinity Fraction Collector / Agilent G1364C 1260 infinity Auto Sampler Agilent 1260 infinity Fraction Collector used Agilent G1346C

Performance Specifications Agilent 1200 Series ANALYTICAL SCALE Autosampler (G1364C)

Trigger modes

Time slices, Peak (threshold, up- / downslope), Timetable (combination of time intervals and peak) and Manual trigger (supported only with G1323B Control Module)

Agilent 1200 Series DAD/MWD detectors (G1315A/B/C, G1365 A/B/C), the Agilent 1200 Series fluorescence detector and the Agilent G1946C/D, G1956A/B LC-MSD are fully supported other detectors can be used but are not supported for fraction collection.

Operating modes

Discrete fractions: default mode for all vessels. The flow is diverted to waste, while moving from one vessel position to the next vessel position

Continuous flow: optional, available only when using the deep well plates. It is possible to move from one well plate position to the next one without diverting the flow into the well plate to waste Needle into location: Needle pushes into the vessel as deep as specified, for the use with capped vials and test tubes and well plates with closing mats

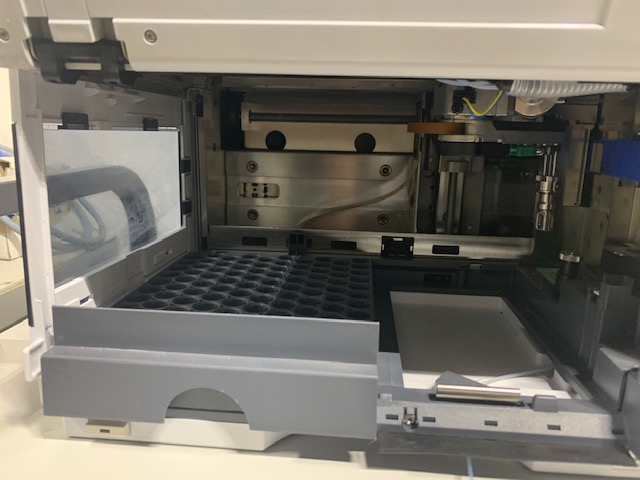

Fraction vessel capacities and trays

Droplet setup mode: The tip of the fraction collector needle will initially move down to the bottom of the well. Then it will slowly move upwards while the fraction is collected. The droplet setup mode enables the fraction collector to collect small fractions without bubbles.

Specification

• 4 x well-plates full tray (MTP)*

• 2 x well-plates std. tray + 10 funnels with external containers* (+ 1 half tray)

• 2 × well-plates std. tray (MTP) + 10 × 2 ml vials* (+ 1 half tray)

• 100x2mlinstd.tray(+1halftray)*

• 3x40x2mlinhalftray*

• 3 x 40 funnels in half tray

• 3x15x6mlinhalftray*

• Full tray with 40 test tubes (30 mm OD, max. height 48 mm, ~20 ml vol.)

• Full tray with 60 test tubes (25 mm OD, max. height 48 mm)

• Full tray with 126 test tubes (16 mm OD, max. height 48 mm)

• Full tray with 215 test tubes (12 mm OD, max. height 48 mm)

Installed trays are automatically detected and identified.

Installed plates and vials can be detected when operating in the needle into location mode

* max. height can be extended by using the short needle assembly G1364-87202

maximum tube / plate height

48 mm with long needle assembly G1367-87200

75 mm with short needle assembly G1364-87202

Maximum tube volume

ca. 20 ml with 48 mm test tubes,

ca. 30 ml with 75 mm test tubes or unlimited,

if funnels are used with external containers.

Maximum flow rate

10 ml / min (depending on viscosity and generated back pressure, max. 6 bar at the diverter valve).

The analytical scale fraction collector can be modified for flow rates > 10 ml/min.

delay volumes [μl]

Fraction collector inlet to diverter valve: ~50 (typical, depends on the length of the tubing) Diverter valve: ~15

Diverter valve to needle: ~10

Needle: ~4

delay calibration sensor

Single wavelength absorbance detector working at 654 nm, consisting of a LED and a photo diode

diverter valve

3/2 Diverter valve with low internal volume (15 μl), switching time < 100 ms, maximum operating pressure 6 bar

cooling

Optional (with additional G1330B), performance depending on ambient conditions and the volume of collected fractions

maximum capacity

3 fraction collectors in parallel plus one recovery fraction collector connected via 12-Position, 13-Port Selector valve (PN G1160A)

GLP features

Early maintenance feedback (EMF), electronic records of maintenance and errors

interfaces

- Controller-area network (CAN).

- optional; LAN or external contacts interface

- RS232C,

- APG-remote (for remote start / stop signals to / from other modules)

- Interface to G1330A Thermostat

- CAN-DC-out for operation of Agilent approved external devices like valves

safety features

Leak detection and safe leak handling, error detection and display, exhaust fan for fume extraction of hazardous vapors